RENNtech Engineering

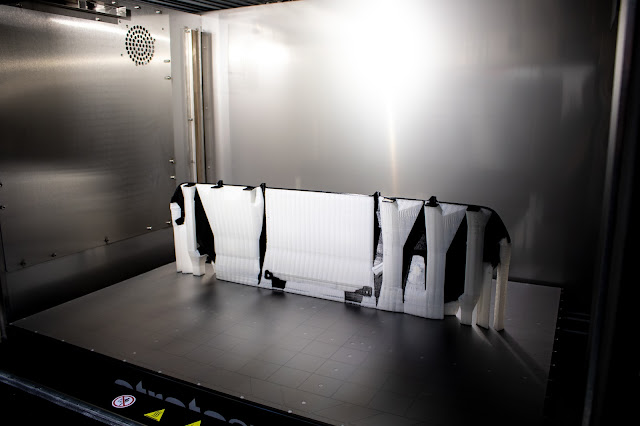

Stratasys F770 3D Printer - First in Florida

The use of 3D printing helps lowering cost and lead time of production parts though verifying concepts and fitment, and shortens the time-to-market for new products. This allows RENNtech to introduce new products to the market at competitive prices without compromising design, quality or time.

“3D printing has always been a great tool for rapid prototyping, but there’s a common problem of build volume being too small. With the F770 is capable of producing large parts in one or two pieces instead of five or six. This will enable us to design, and prototype printed parts we have not attempted before; like hoods, widebody kits, and doors. The upcoming years will be very imaginative and exciting, I cannot wait to see what we come up with. “ – Connor Salley, Engineer RENNtech

The Stratasys F770 uses the highest quality ABS and ASA materials which can be used for large size prototypes or lightweight production pieces. The first production piece from the Stratasys F770 will be the Eurostyle Bumper Plate designed for the C257 CLS -chassis.

Designed in house, the Eurostyle Bumper Plate is designed to eliminate the unsightly American “bumperette”, replacing it with a form-fitting insert for a sleek look. After printing, the part will be test-fitted and then finished in either primer or gloss black before made available for our customers.